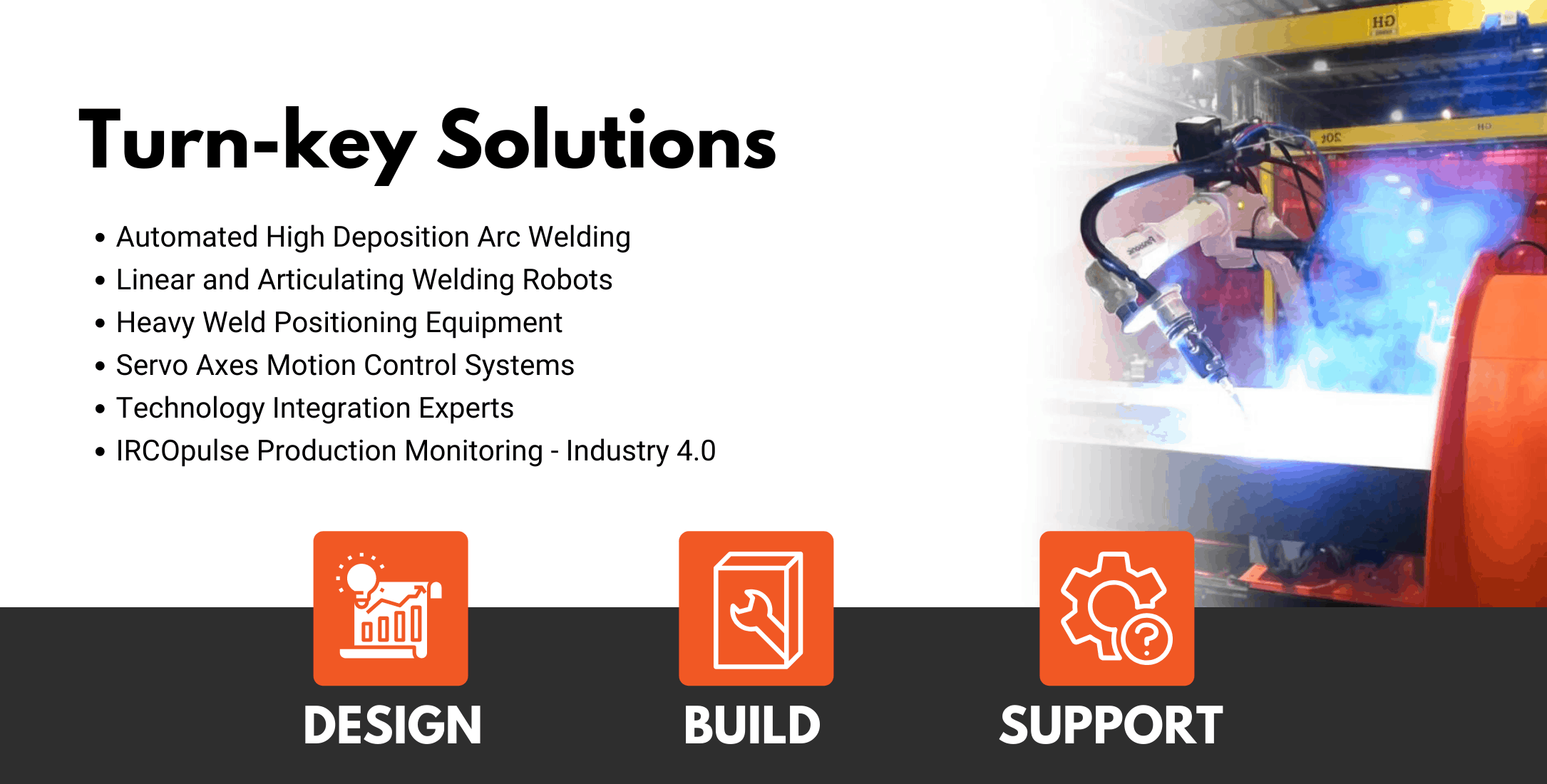

Welding Automation

Hard Automation

Robotic Automation

Which type of automation is right for you?

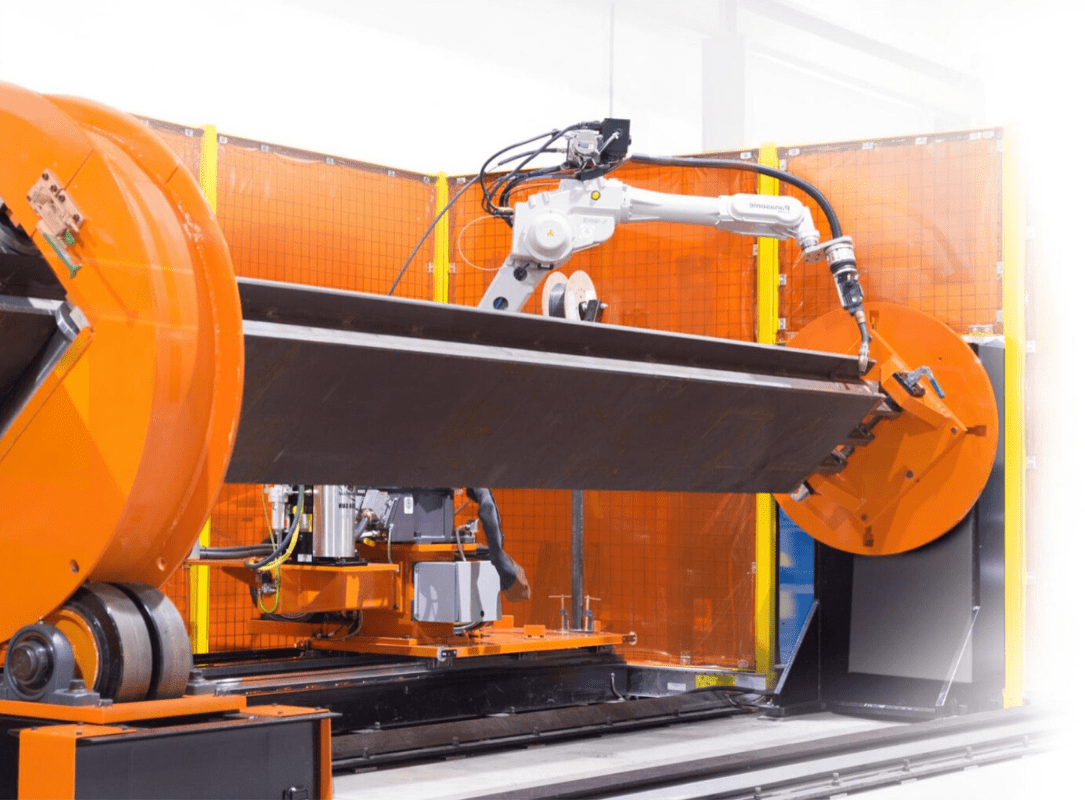

Robotic Automation

AT A GLANCE...

Flexible automation

6 or more axes

Offline programming

Autonomous Automation

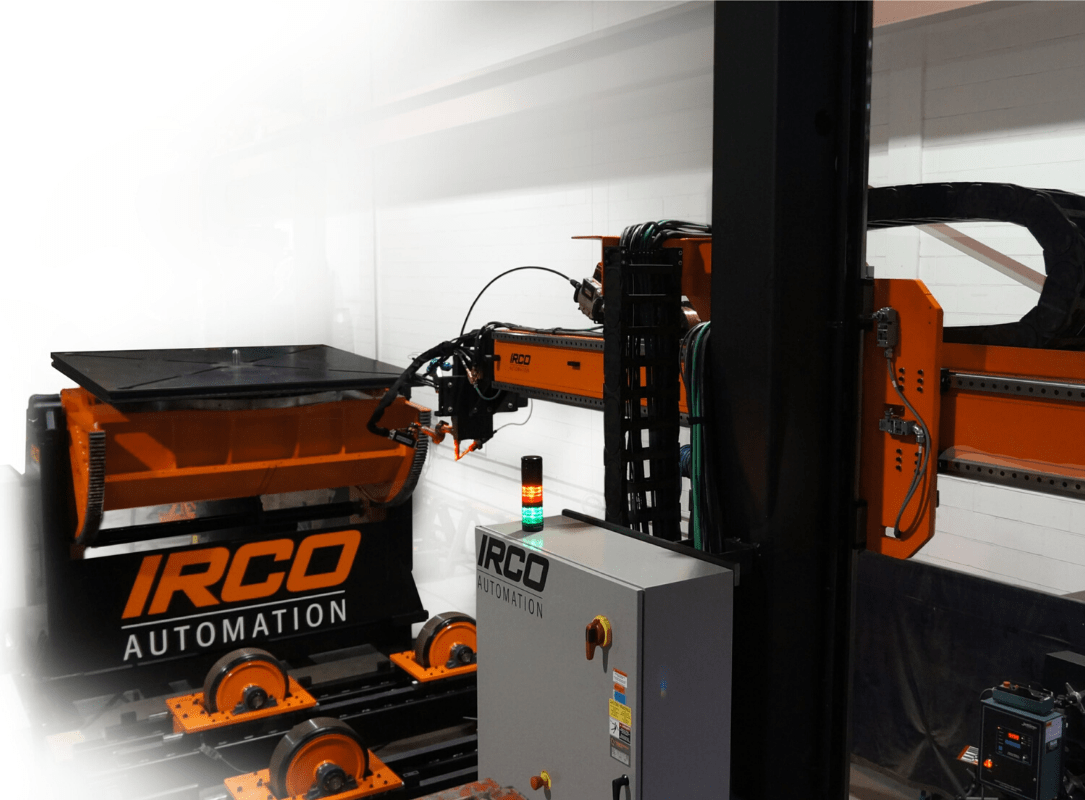

Hard Automation

AT A GLANCE...

Fixed Automation

Six or fewer axes

PLC-based programming

Semi-automatic with a robust interface

Project Journey

IRCO Automation is an industry leader in the development of welding automation for industrial applications. Our design philosophy is to "start at the arc", making sure we understand your weld process and requirements. The philosophy allows us to provide a solution that integrates positioning equipment, power supplies, controls and software that's designed to maximize productivity, safety and ROI. Building a lasting relationship through the journey, here are some of the stages you can expect:

DISCOVERY

Discovery process to learn about your current needs, processes, and capabilities to understand what the solution/ system will need to help solve, improve, and do.

CONCEPT

With information about your current needs, processes, capabilities, and with a reflection on your ROI, our team creates a concept and budgetary proposal for you to review.

PROPOSAL

Presentation and discussion to review the proposed design, timeline, and engage in the procurement process.

DESIGN BUILD

Our team does the necessary steps to engineer, manufacture, and test the system in our facility. At the end of this stage, your team will be invited to view and complete a FAT with us and begin initial training.

INSTALL

After making any required modifications, the system is prepared for relocation and shipped to your location. Our team will travel to the site to assist with the install and provide necessary training as part of the SAT.

ON GOING SUPPORT

After the installation is complete our service and support team will actively provide support, parts, training, or repairs, etc. as needed to further your experience as our customer

interested in learning more? Check out these blog posts from our team.

IRCO’s expertise in the development of welding automation solutions resides in-house. Our team of welding, mechanical, electrical and controls professionals have years of experience implementing automation systems.